Megger ODEN Primary Current Injection Test System

The Megger ODEN is a world-leading primary injection test system designed for dependable high-current testing of protective relays, circuit breakers, and current transformers. With decades of expertise built into its design, the Megger ODEN combines cutting-edge measurement technology with unmatched reliability and portability. For engineers working in substations, industrial facilities, and power plants, the primary current injection tester is the tool of choice for accurate results in mission-critical environments.

Unlike conventional test methods, the Megger ODEN primary injection test set delivers repeatable, high-current performance with fast set-up, advanced control, and a modular design that adapts to the most demanding applications. Each component is portable, easy to assemble, and designed for efficient use in tight switchgear rooms or field environments.

What is Primary Injection Testing?

Primary injection testing is a cornerstone of electrical system reliability. It involves applying a controlled high current directly into the primary side of a circuit breaker, relay, or transformer to validate protection systems under real operating conditions. Unlike secondary injection tests that simulate signals electronically, a primary injection test ensures the entire system — from primary conductor through to protection relay — operates as designed.

This is critical for:

- Circuit breaker verification – confirming trip curves and response times.

- Relay commissioning – ensuring settings and behaviour align with protection schemes.

- Current transformer checks – verifying accuracy under full-load conditions.

- System safety – preventing failures that could result in downtime, costly repairs, or safety incidents.

The Megger ODEN takes this essential practice further by combining high output current with sophisticated measurement features, giving engineers complete confidence in their protection systems.

Power, Precision and Portability

At the heart of the Megger ODEN primary injection test system is its modular design. The system consists of a control unit and one, two, or three current units, offering up to 13 kA for one second and 3800 A continuous output.

Three current unit versions are available:

- S-unit – standard configuration for everyday testing.

- X-unit – identical to the S-unit but with an additional 30/60 V output, ideal for CT and ground grid tests.

- H-unit – capable of delivering even higher currents for demanding applications.

Every part of the Megger ODEN is designed with portability in mind. A compact transport cart allows the system to be moved easily into confined switchgear rooms. Assembly and connection are quick, meaning engineers spend less time setting up and more time completing accurate primary injection test routines.

Advanced Control and Measurement

The control unit is where the Megger ODEN demonstrates its advanced engineering. Features include:

- Dual measurement channels – display current, voltage, time, and phase angle simultaneously.

- Integrated calculations – automatically show impedance, resistance, power factor (cos φ), and transformer ratios.

- Fast-acting hold function – captures short-duration readings that could otherwise be missed.

- I/30 function – enables preset current with low injection to reduce heating and maintain measurement accuracy.

These capabilities make the primary current injection test set more than just a source of current. It is a precision measurement tool that provides actionable data, enabling engineers to diagnose problems quickly and carry out comprehensive system verification.

Megger ODEN Key Features:

- The most advanced primary injection test system for breaker testing, CT verification, and ground grid evaluation.

- Modular system tailored to the needs of any application.

- Compact and transportable, ensuring easy movement in restricted areas.

- Programmable duty cycles for long-duration heat-run and endurance tests.

- Built-in calculations for rapid assessment of system parameters.

The Megger ODEN is a practical investment that simplifies testing while raising the standard of accuracy and safety.

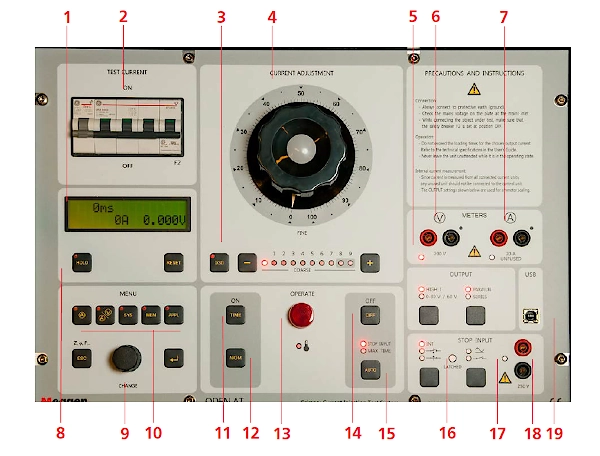

ODEN Front Panel Key:

- Display – shows time, current, voltage, phase angle, and key electrical parameters.

- Miniature circuit breaker – safe disconnection of output current.

- Current reduction – I/30 function to limit heating during setup.

- Fine adjustment – precise control of current output.

- Indicator lamps – show which measurement mode is active.

- Voltmeter input – for voltage or micro-ohmmeter measurement.

- Ammeter 2 input – for external current or CT secondary testing.

- Hold function – freezes readings for short-duration events.

- Selection knob – menu navigation and value changes.

- Setting buttons – quick access for current, voltage, memory, and test modes.

- Injection button – starts current injection and timing.

- Momentary injection – applies current only while pressed.

- Warning lamp – lit during current generation.

- Manual shut-off – instantly halts output.

- Automatic stop – ends injection when conditions are met.

- Stop-condition indicator – shows when a trigger is reached.

- Status indicator – confirms contact closure or voltage presence.

- Stop input – freezes readings or stops injection on trigger.

- USB port – transfers test data to a PC.

Applications of the Megger ODEN:

Primary Injection Testing and Breaker Testing

The Megger ODEN delivers the high currents required for breaker testing, while precise timing measurements confirm trip curves and operating limits.

Current Transformer Testing

For CTs, the system can simultaneously display the primary current and either the secondary current or turns ratio, with polarity and phase displacement clearly indicated.

Heat Runs

The Megger ODEN is ideal for heat-run testing. Current can be applied continuously or via programmable intervals, with results logged over extended periods.

Automatic Reclosers and Sectionalisers

By simulating real operating conditions, the ODEN measures operating limits, timing sequences, and lockout behaviour of reclosing relays.

Ground Grid and Safety Devices

The ODEN is trusted for testing ground grids and safety-ground devices, ensuring system integrity and compliance with safety standards.

Why Choose the Megger ODEN Over Alternatives?

The Megger ODEN stands apart from other current injection testers through its unique combination of features:

- High compliance voltage ensures accurate results even with long cable runs.

- Flexibility with 46 possible system configurations.

- Portability that makes it genuinely practical for both field and workshop environments.

- Proven track record in the most demanding industries, from heavy industry to nuclear power.

While other systems may offer partial functionality, the Megger ODEN primary current injection tester provides an integrated solution that saves time, increases reliability, and delivers confidence.

Industries That Benefit Most

- Utilities – for commissioning substations and maintaining breaker fleets.

- Industrial facilities – ensuring plant reliability and preventing costly downtime.

- Renewable energy – validating grid protection in wind and solar installations.

- Nuclear power – where safety, compliance, and reliability are critical.

At Diablo Canyon nuclear facility in the USA, the Megger ODEN cut breaker testing from seven days to just four, saving over $30,000 annually. This case highlights the ODEN’s value as both a primary injection test system and a driver of efficiency.

Proven in Demanding Environments

With more than 40 unique configurations available, the Megger ODEN adapts to virtually any test requirement. It has been deployed in power plants, substations, and industrial complexes worldwide. Built for reliability, it withstands tough operating conditions while consistently delivering the precision needed for protection testing.

Wherever dependable system testing is required, the Megger ODEN is the proven solution.

Available Megger ODEN AT Options:

The Megger ODEN primary injection test system is available in a wide range of configurations to meet different testing requirements. Each system consists of a control unit and one or more current units, with options for transport carts and accessories.

Control Units

- ODEN AT Control Unit – Part No: ODENAT-CU

Current Units

- S-Unit (Standard) – Part No: ODENAT-S

- X-Unit (with 30/60 V output) – Part No: ODENAT-X

- H-Unit (High Current) – Part No: ODENAT-H

System Configurations (examples)

- ODEN AT/2X (Control + 2 × X-units) – Part No: ODENAT-2X

- ODEN AT/3S (Control + 3 × S-units) – Part No: ODENAT-3S

- ODEN AT/3H (Control + 3 × H-units) – Part No: ODENAT-3H

Accessories

- Transport Trolley – Part No: ODENAT-TROL

- Cable Set – Part No: ODENAT-CABLE

- Software Package for Data Transfer – Part No: ODENAT-SW

(For full ordering details, refer to the Megger ODEN AT Data Sheet.)

The Takeaway:

The Megger ODEN represents the gold standard in primary injection test systems. With its modularity, portability, and advanced control, it is the ultimate primary current injection tester for engineers who demand accuracy, efficiency, and reliability.

Whether you are commissioning new installations, maintaining existing infrastructure, or validating safety-critical systems, the Megger ODEN primary injection test set ensures every test is delivered with confidence. It is not just a current injection tester — it is a complete solution for ensuring protection systems perform when it matters most.