FLUKE ii500 Acoustic Imager

- See sound and detect problems early.

The FLUKE ii500 Acoustic Imager is a cutting-edge tool that transforms the way industrial maintenance teams detect leaks and faults. Instead of relying on old, time-consuming methods like spraying soapy water or using handheld ultrasonic detectors, the FLUKE acoustic imager lets you see sound. By visualising leaks and electrical discharge in real time, it helps you act quickly, avoid downtime, and keep your plant safe.

This model sits at the top of the ii-Series range, offering excellent sensitivity and performance. Whether you’re working with compressed air, gas, steam, or vacuum systems, the FLUKE ii500 ensures fast inspections without interrupting production.

Why Choose the FLUKE ii500?

1. Reduce Downtime and Save Money

Unplanned stoppages can cost tens of thousands of pounds per hour. With the FLUKE acoustic imager, you can spot leaks or electrical discharges early, giving your team time to plan repairs before small issues become major failures.

2. Boost Efficiency

Traditional methods require operators to get very close to the equipment, often crawling under machines or climbing ladders. The FLUKE ii500 Acoustic Imager allows safe, contact-free inspections from up to 50 metres (164 feet) away. This means you can scan large areas in minutes - even during normal operating hours.

3. Improve Safety

Because inspections are done from a distance, your team avoids unnecessary exposure to hazardous areas. With clear visuals and sound mapping, there’s no guesswork, no spraying chemicals, and no risky physical access.

▶ Video - FLUKE ii-Range of Acoustic Cameras:

How It Works – SoundSight™ Technology

The FLUKE ii500 uses an array of sensitive microphones to capture sound waves. These signals are processed into a SoundMap™, which is then blended with a visual image on a 7-inch touchscreen display. This lets you “see” the source of the leak or discharge, even in noisy industrial environments where the human ear can’t detect anything.

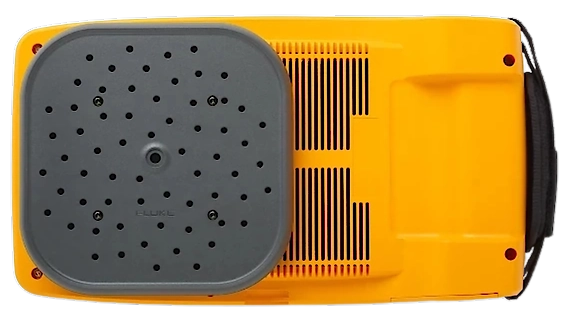

↑ 64 digital MEMS microphones on the back of the FLUKE ii500

▶ Video - See the FLUKE Acoustic Cameras in Action:

Key Features of the FLUKE ii500 Acoustic Imager

- LeakQ™ Mode - Estimates leak size, leak rate, and potential energy costs directly on the device.

- Detection Range - Up to 50 metres depending on conditions.

- Frequency Band - 2 kHz to 52 kHz, perfect for compressed air and gas leak detection.

- Display - Large 7” capacitive LCD touchscreen (1280 x 800 resolution) for easy navigation.

- SoundMap™ Imaging - Blended visual and acoustic images for accurate pinpointing.

- Memory - 20 GB internal storage (over 5,000 pictures and nearly 1,000 videos).

- Battery Life - Up to 6 hours continuous operation, with rechargeable lithium-ion pack.

- Portability - Lightweight design (2.1 kg), rugged carrying case, and adjustable hand and neck straps.

- Ease of Use - One-button image capture, intuitive menus, and annotation tools for tagging inspections.

What comes with the FLUKE ii500?

- FLUKE ii500 Acoustic Imager

- Rugged lithium-ion battery pack

- Charging bay with universal AC adapters

- USB-C cable for data transfer

- Rugged hard carrying case

- Adjustable hand and neck straps

- Sensor array protection cover

Typical Applications:

- Compressed Air Leak Detection - Quickly identify leaks in plant compressed air systems, saving energy and cost.

- Gas and Steam Leaks - Detect and repair leaks in industrial gas pipelines or steam systems without halting production.

- Partial Discharge - Locate early signs of insulation failure in high-voltage equipment, preventing catastrophic breakdowns.

- General Maintenance - Use during routine checks to ensure assets run efficiently and safely.

❓Frequently Asked Questions (FAQ)

Q1: What makes the FLUKE ii500 different from other leak detectors?

A. The FLUKE acoustic imager doesn’t just detect leaks - it shows them visually, making inspections faster, easier, and safer compared to ultrasonic detectors or soapy water methods.

Q2: Can I use the FLUKE ii500 while machines are running?

A. Yes. One of its biggest advantages is that inspections can be carried out during normal operations, avoiding costly downtime.

Q3: How accurate is the LeakQ™ feature?

A. LeakQ™ provides a scale (1–10) with estimated leak rate and cost, helping you prioritise repairs and maximise energy savings.

Q4: Is the FLUKE ii500 suitable for electrical inspections?

A. While the ii500 is primarily designed for leak detection, the higher-end ii915 model includes PDQ™ and MecQ™ modes for in-depth electrical and mechanical inspections.

Q5: How long does the battery last?

A. A fully charged lithium-ion battery runs for up to 6 hours, making it suitable for full-day inspections.

The Takaway

The FLUKE ii500 Acoustic Imager is a reliable, high-performance solution for industrial maintenance teams that need fast, accurate, and safe leak detection. By helping you see sound, it ensures you cut energy waste, improve safety, and stay ahead of costly unplanned downtime.

Investing in the FLUKE acoustic imager means protecting your operations, saving money, and boosting efficiency - all with a tool that’s simple enough for technicians to use with minimal training.