The Importance of Oil Dielectric Breakdown Voltage

BDV Testing Across Seven Key Industrial Sectors

In high-voltage electrical systems, insulating oil provides essential cooling and dielectric insulation. Over time, oil degrades due to moisture, particles, and chemical ageing—raising the risk of transformer oil breakdown and failure. That’s why the BDV test of transformer oil is a vital diagnostic tool. It measures the voltage at which the oil fails electrically, helping engineers determine if it retains high dielectric strength.

By increasing the voltage between two electrodes immersed in a transformer oil sample, engineers observe the point of failure. A high oil BDV reading suggests dry, clean oil, while a low reading indicates contamination. This breakdown voltage test of transformer oil supports early detection of faults and plays a key role in maintaining reliable operation of critical assets.

1. Utilities and Power Generation

Utilities routinely test for transformer oil breakdown voltage in substations to ensure grid resilience. A failure in transformer insulation could cause widespread blackouts. Engineers use BDV testers and BDV test kits to evaluate oil in service. Spotting a low transformer oil BDV value early allows for corrective actions like filtration or replacement—preventing costly failures.

Many follow transformer oil BDV test standards such as IEC 60156 to ensure consistency and compliance. A minimum breakdown voltage is typically required for oil to remain in service.

2. Industrial Facilities

Manufacturers, data centres, and mining operations depend on uninterrupted power. Routine BDV testing of transformer oil ensures that oil-filled equipment—like HV motors and backup transformers—stays safe under load. If the transformer oil BDV value is close to the minimum breakdown voltage, preventive measures can be taken before insulation failure occurs.

In harsher settings like mining, portable oil breakdown voltage testers allow quick, onsite decisions. Paired with oil viscosity testing equipment, this testing offers a comprehensive view of both thermal and dielectric oil performance.

3. Maintenance and Service Providers

Maintenance contractors offer vital services to firms lacking in-house testing capabilities. These companies perform on-site BDV test of transformer oil using portable instruments. They evaluate each transformer oil sample against industry standards, quickly identifying risks.

A sudden drop in BDV can signal contamination or water ingress. Acting swiftly ensures reliable operation and extends equipment lifespan, while also preventing costly breakdowns and unplanned outages.

4. Transformer Manufacturers

OEMs are responsible for ensuring that new transformers meet all technical requirements before shipping. This includes validating the high dielectric strength of the oil used. During production, they test each transformer oil sample using calibrated oil dielectric strength testers.

By doing so, manufacturers ensure the minimum breakdown voltage threshold is surpassed. This process prevents insulation failure between core and windings and guarantees long-term performance.

5. Oil Suppliers and Refiners

Insulating oil producers test for transformer oil breakdown during quality control. They use oil breakdown voltage testers and oil viscosity testing equipment to verify each batch meets dielectric and thermal standards.

BDV testing confirms the product delivers high dielectric strength, while viscosity tests check flow and cooling performance. Only oil that passes all criteria—including the required minimum breakdown voltage—is released to market.

6. Laboratories

Specialist labs provide third-party oil testing, often when deeper insight is required. They use high-precision oil dielectric strength testers to analyse customer transformer oil samples.

Tests follow transformer oil BDV test standards, and results may indicate oil failure, ageing, or contamination. Reports detail whether the oil maintains adequate transformer oil BDV value or risks transformer oil breakdown, offering practical maintenance recommendations.

7. Qualified Technicians and Engineers - Any Sector (Contracting or In-House)

Skilled personnel ensure accurate testing and safe procedures. Using BDV testers, they evaluate samples directly from equipment. Proper sampling techniques prevent air and moisture from skewing results.

These technicians understand how to interpret borderline results—such as oil just above the minimum breakdown voltage—and advise on further actions. Their expertise ensures compliance with industry standards and contributes to the reliable operation of critical infrastructure.

Modern Oil BDV Testing Equipment

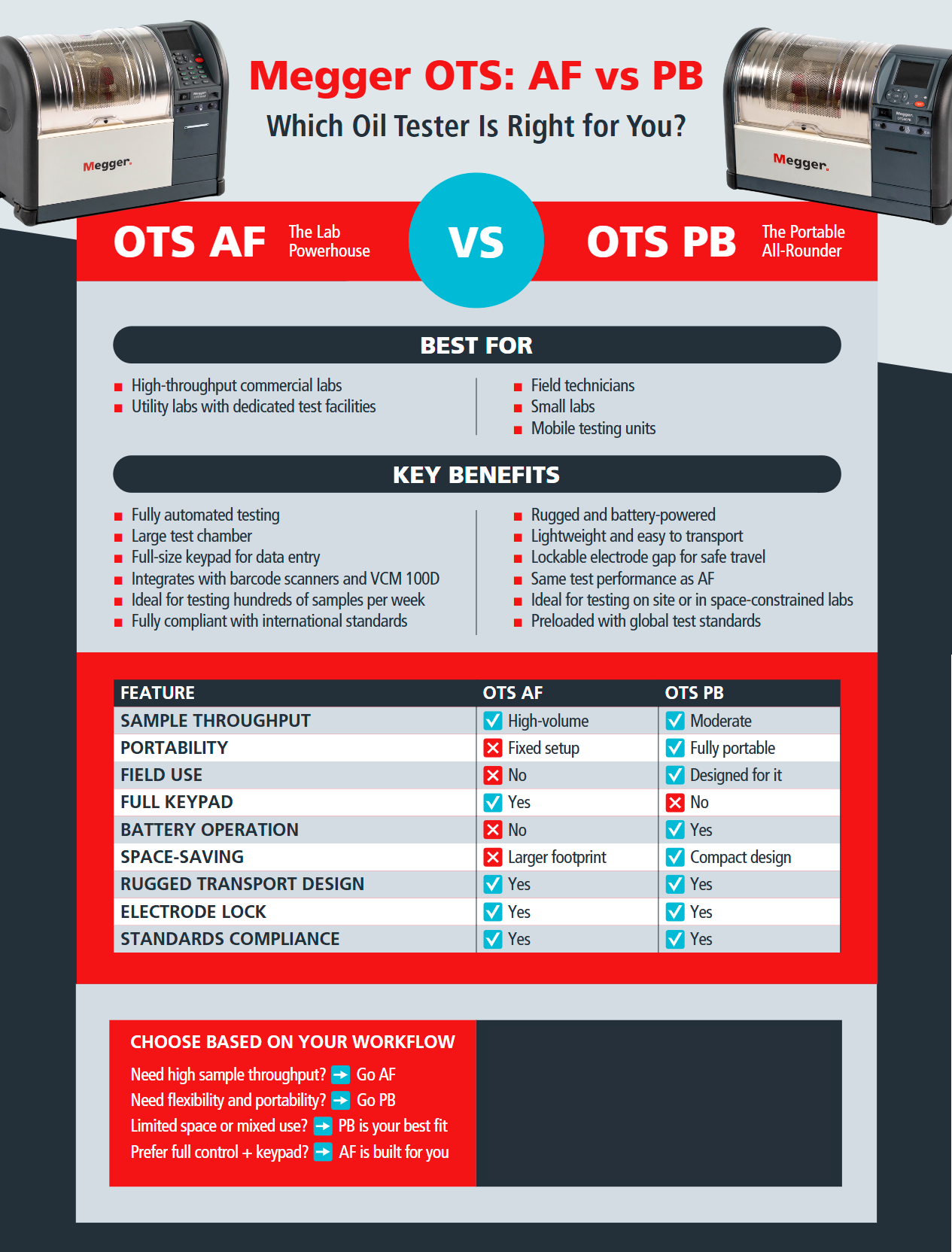

Modern oil BDV testing equipment is designed for safety, accuracy, and portability. Engineers can now use compact, automated testers with programmable test standards. Many include digital data logging, enclosed test chambers, and safety interlocks.

These BDV test kits help field and lab staff measure dielectric strength efficiently and consistently. Whether confirming high dielectric strength in new oil or diagnosing potential transformer oil breakdown, these devices support proactive maintenance.

Frequently Asked Questions (FAQ)

Q1: What is the purpose of BDV test of transformer oil?

A. To measure the dielectric strength of insulating oil and determine whether it can safely insulate core and windings under electrical stress.

Q2: What defines a pass or fail?

A. Results are compared against transformer oil BDV test standards. Failing to meet the minimum breakdown voltage indicates that the oil needs processing or replacement.

Q3: How often should testing be performed?

A. Annually as a baseline, though more frequent testing may be needed for high-risk or critical equipment.

Q4: Which equipment is used?

A. Oil dielectric strength testers, oil breakdown voltage testers, and in some cases, oil viscosity testing equipment to assess thermal properties.

VIEW ALL OIL TESTERS

Ready to Upgrade Your Oil Testing?

Get the right test equipment at the right price — contact us now for a fast, competitive quote.

💬 Talk to the Experts

Our team is ready to discuss your requirements. Get straightforward advice, proven performance, and reliable solutions that work.

📍 Want to See It in Action?

We’ll bring the demo to you. Book a live on-site demonstration and see our test equipment perform in real-world conditions.